- Bolster size: 4500×1800、3500×1800、3000×1500

- Largest Progressive DIE Press machine

in Japan - Compatible with Ultra High Tensile Strength Steel with a Leveller-feeder

Head Office & Factory Facility

(Opened on the 22nd of September, 2016)

Lot Area: 14,000㎡ Floor Space:4,500㎡

Our new factory combines Head Office,

Machining and Assembly+Press buildings.

Our new Sasayama HQ facility combines our Head Office with factory facilities in one location.

Our new factory consists of Head Office, Machining and Assembly+Press buildings with Lot Area of 14,000㎡, Floor Space of 4,500㎡

This allows us to produce stamping dies of the highest quality more efficiently, and deliver dies to our customers sooner than ever.

We only use the highest quality and state of the art machines for our die manufacturing.

Re-branded with an English Logo in order to reflect our global activities and expressed it with the light sign board of Company's new building.

Comfortable working environment allows for focusing on work and higher productivity

New facility allowed us to greatly reduce inefficiency of splitted design work and manufacturing work elements between the 2 sites by aggregation of the elements in one place.

Several kinds of Cranes are available; 20 ton Overhead Crane thru the Semi-Portal and Parent-Child Cranes.

Enabled the large die handling and safety to coexist

1600ton, 1000ton, 600ton TRYOUT PRESS MACHINES

(AIDA ENGINEERING, LTD.)

In recent years, there's a clear movement of light-weighting in automotive industry for the purpose of improving the fuel efficiency. In line with it, all of Japanese major car manufacturers are proceeding to abopt Ultra-High Tensile Strength Materials. Eventually the stamping dies to produce such automotive parts are becoming bigger in size, therefore in order to respond to it, at Sasayama we introduced the large press machines such as 1600ton, 1000ton and 600ton for trial pressing. All those presses are equipped with Leveller-Feeders respectively so that they are compatible with Progressive Dies.

1600ton PRESS MACHINE

Bolster size:4500×1800

Equipped with a Leveller-feeder compatible with Thick Ultra High Tensile Strength Steel Sheet

Largest PRG DIE Press machine in Japan

1000ton PRESS MACHINE

Bolster size:3500×1800

Stroke speed ~60spm

Equipped with a Leveller–feeder compatible with up to 1200mm wide steel sheet

Compatible with PRG DIE

600ton SERVO PRESS MACHINE

Bolster size:3000×1500

Equipped with a Leveller-feeder and compatible with PRG DIES

Equipped with DIE CUSHION

Tryout pressing equivalent to the customer's mass-producing conditions possible

by inputting the assigned slide motion to SERVO PRESS

Willing to respond to the customer's requirement for DIES making use of

the unique characteristics of SERVO PRESS and such joint development

LARGE-SIZED DOUBLE-COLUMN MACHINING CENTER

Equipped with Pallet Changer

Side cutting work available by 90° angular head

Bed size:5000×2500

Equipped with Pallet Changer → Continuous 24-hour operation by off-line set-up

Side cutting work available by 90° angular head

Long hours, continuous operation with a 120-piece auto tool changer (ATC)

Newly installed in 2016, aiming for further manufacturing leadtime reduction

Bed size: 5000x2500

Overhauled this covertional high-rigid type machine in 2016, and now it looks new

- 6-Station Horizontal Machining Centers

(One of them: 5-Axis Horizontal Machining Center)

- High precision machining by operating in a Thermostatic room

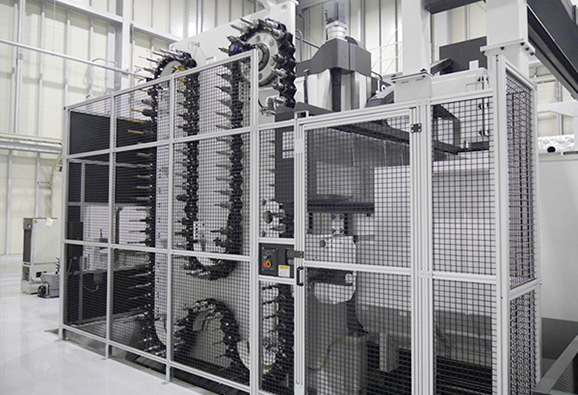

MACHINING CENTER ROBOT CELL PRODUCING SYSTEM Center Robot

6-Station Machining Centers

(One of them: 5-Axis Machining Center)

High precision machining by operating in a Thermostatic room

Automatic workpiece exchange by dynamic Articulated Robot

Thanks to this stable temperature condition, 90 stage palette

stocking and the robot equipment, high precision machining and

high productivity are now coexisting not only for the die

manufacturing but also for machining for other industries.

*Please push ▶ for starting movie

Ultra-Surface grinding(die plates, etc.)

Machining of workpieces in size of 600×300、800×400 is possible with high repeatability and submicron flatness and parallelism.

Ultra-Precision grooving machining and form fabrication

High repeatability to the submicron enables accurate grooving and form fabrication of connectors, etc.

Contouring and shape fabricating

Contouring by simultaneous control of vertical/cross axes and shape fabricating by simultaneous control of vertical/longitudinal axes are possible with outstanding accuracy.

On-the-Machine 3D Measurement↓

Ultra mirror finish machining

(for press and resin dies, etc. )

Accurate infeed is possible even for high-number grinding wheels. Furthermore, mechanical fluctuation is eliminated to achieve higher quality.

This Super Precision Forming Surface Grinder materializes the revolutionary grinding work and its advantages can be summarized as below:

Increases machining efficiency

Several times higher machining efficiency in surface and form grinding than ever

Improves efficiency and accuracy in grinding hard-to-cut materials

Hard-to-Cut materials:

Hard Metal, SiC, Alumina, Other Ceramics, SUS, Inconel, etc.

Prevents accuracy deterioration caused by grinding heat

Suppresses distortion and warping of the workpiece

Realizes several times faster grinding

Several times deeper grinding depth or faster feed speed compared with conventional machining realized and reduces the operation time drastically, thanks to the new coolant mechanism and other improvements